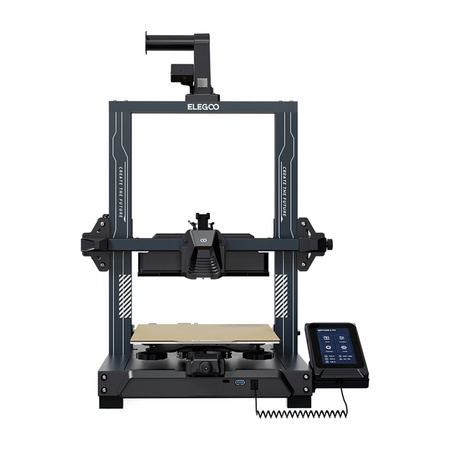

ELEGOO Neptune 4 Pro 3D Printer

Subscription products in your shopping cart

Set one delivery frequency for all subscription products in your cart every:

Subscription products in your shopping cart

ELEGOO Neptune 4 Pro 3D printer

The ELEGOO Neptune 4 Pro is a state-of-the-art FDM (Fused Deposition Modelling, a fused deposition technology) 3D printer that combines high speed, precision and robust design. Based on the Klipper motherboard, it offers a large working area of 225 × 225 × 265 mm and a print temperature of up to 300°C, and allows the use of a wide range of filaments - from PLA (Polylactic Acid) and PETG (Polyethylene Terephthalate Glycol, modified polyethylene terephthalate with glycol) to ABS (Acrylonitrile Butadiene Styrene, acrylonitrile-butadiene-styrene copolymer), TPU (Thermoplastic Polyurethane) or nylon. With a powerful extruder and automatic 121-point levelling, the Neptune 4 Pro can handle both rapid prototyping and long, demanding technical prints.

Fast printing without compromise

The printer reaches a maximum speed of 500 mm/s, with a recommended 250 mm/s guaranteeing excellent quality with fast turnaround times. Backed by the Klipper motherboard, a powerful ARM (Advanced RISC Machine, advanced RISC architecture) 64-bit 1.5G quad-core processor and features such as Input Shaping and Pressure Advance - it provides an exceptionally smooth model surface and even filament stamping. It is the perfect choice for those who expect not only accuracy but also real time savings.

Efficient cooling system, clever table design

Two double-sided 4015 fans and four 4020 fans ensure effective heat dissipation and cooling of the printed models. What's more, the unit's heating table is divided into two segments with different wattages - 150 W and 100 W. This solution guarantees lower power consumption and protects against overheating, resulting in more stable and safer operation.

Improved hotend and powerful extruder

The Neptune 4 Pro is equipped with a high-performance direct-type extruder with twin gears, which ensures precise and stable filament feeding, regardless of the type of filament. In addition, the hotend with its improved design uses a copper-titanium thermal tube and a nozzle capable of operating at 300°C. This solution allows printing from a wide range of materials, including those requiring higher temperatures and better flow.

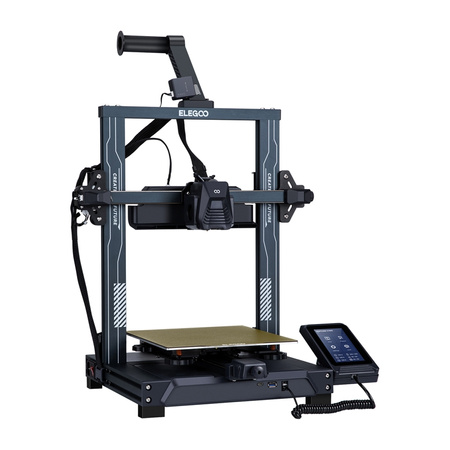

Steering stability and structural rigidity

The printer is equipped with metal X- and Y-axis guides, which, combined with double U-shaped ball bearings, ensure smooth, precise and stable guidance of the print head. In addition, the reinforced, extended Y-axis profile increases the rigidity of the entire structure, resulting in higher print quality, especially at high speeds.

Automatic levelling and flexible platform

The printer uses automatic table levelling at as many as 121 points (11×11 grid), which ensures perfect adhesion and a perfectly levelled first layer. In addition, the user can use the knobs underneath the working platform to manually adjust the level - for even greater accuracy and full control over the printing process.

Intuitive operation and flexible communication

A detachable 4.3" touchscreen allows convenient previewing of the model and stopping printing. In addition, the printer allows files to be transferred via USB (Universal Serial Bus) or LAN (Local Area Network).

Additional capabilities

Thanks to a filament sensor and a restart function after an interruption, you can be sure that printing will not fail, even if something unexpected happens. LED (Light Emitting Diode) lighting at the nozzle makes it easy to see details up close, while an additional LED strip provides even illumination across the entire working area.

More space for your ideas

The Neptune 4 PRO offers a working space of 225 × 225 × 265 mm, allowing you to create both small prototypes and more elaborate models. This volume gives you a great deal of design freedom without having to split models into parts.

| Manufacturer | ELEGOO |

|---|---|

| Model | M6-512 |

| Maximum printing speed | 500 mm/s |

| X, Y axis | All-metal axis guides with double U-shaped ball bearings |

| Pressure Advance function | Yes |

| Input Shaping function | Yes |

| Heating table | 100 W + 150 W, intelligently zone-heated |

| Platform levelling | Automatic at 121 points + booster levelling |

| Working volume | 225 × 225 × 265 mm |

| Extruder type | Improved direct-type extruder with twin gears (291 g) |

| Fan type | 4015 fans with ball bearings |

| Max. fan speed | 10,000 rpm |

| Max. nozzle temperature | Up to 300°C |

| Firmware | Klipper |

| File transfer method | LAN + USB |

| Supported materials | PLA / ABS / TPU / PETG / Nylon |